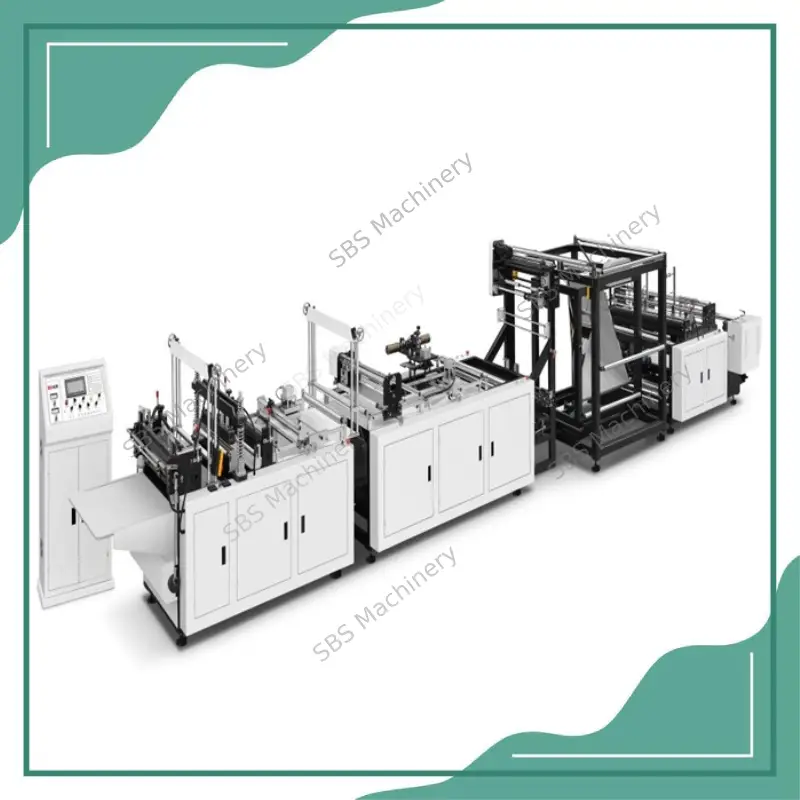

Monolayer Blown Film Machine Plant

Monolayer Blown Film Machine Plant

The Monolayer Blown Film Machine is the right option as this equipment offers a high-speed production solution. It is an effective investment for the packaging sector in India, allowing businesses to achieve a good return on investment (ROI) in cities like Delhi, Mumbai, Bangalore, Chennai, Kolkata, Hyderabad.

Product Description

| Model | Material to be Processed | Screw Die | Barrel Feed Type | Bag Film Width Range | Film Tower Height | Machine Nip Roller Size | Die Type | Winders Station Type | Machine & Main Driver | Connecting Load | Maximum Output | Main Motor | Air Blower |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SBS – 35X | HM/HDPFE/LDPE/BIO/LD | 35 MM | Groove Feed | 100 to 400 MM | 10-12 Feet | 20″ Inch | Stationary Die | Single station with 1 HP motor & driver | Delta make AC Driver | 21 Kw (28 HP) | 25 to 30 Kg./Hr | 7 HP ABB Brand | 3 HP |

| SBS – 40X | HM/HDPFE/LDPE/BIO/LD | 40 MM | Groove Feed | 150 to 550 MM | 10-13 Feet | 26″ Inch | Stationary Die | Single station with 1 HP motor & driver | Delta make AC Driver | 29 Kw (39 HP) | 30 to 40 Kg./Hr | 10 HP ABB Brand | 3 HP |

| SBS – 45X | HM/HDPFE/LDPE/BIO/LD | 45 MM | Groove Feed | 150 to 700 MM | 12-14 Feet | 32″ Inch | Stationary Die | Single station with 1 HP motor & driver | Delta make AC Driver | 32 Kw (42 HP) | 35 to 50 Kg./Hr | 15 HP ABB Brand | 5 HP |

| SBS – 55X | HM/HDPFE/LDPE/BIO/LD | 55 MM | Groove Feed | 250 to 800 MM | 14-17 Feet | 36″ Inch | Stationary Die | Single station with 1 HP motor & driver | Delta make AC Driver | 38 Kw (50 HP) | 50 to 65 Kg./Hr | 20 HP ABB Brand | 7.5 HP |

| SBS – 65X | HM/HDPFE/LDPE/BIO/LD | 65 MM | Groove Feed | 380 to 1200 MM | 16-20 Feet | 52″ Inch | Stationary Die | Single station with 1 HP motor & driver | Delta make AC Driver | 53 Kw (70 HP) | 70 to 80 Kg./Hr | 25 HP ABB Brand | 7.5 HP |